Concrete Building Structure Types: Concrete, a versatile and durable material, has revolutionized construction. Its ability to be molded into various shapes and its inherent strength make it a staple for buildings of all sizes and functions. Understanding the different types of concrete building structures is crucial for architects, engineers, and anyone involved in the construction process. This guide provides a comprehensive overview of common concrete building structure types, outlining their characteristics, advantages, and applications.

I. Cast-in-Place Concrete Structures:

Cast-in-place (also known as site-cast) concrete refers to concrete that is poured and cured on the construction site. This method allows for customized designs and complex shapes, making it a popular choice for unique and intricate structures.

- 1. Concrete Frames:

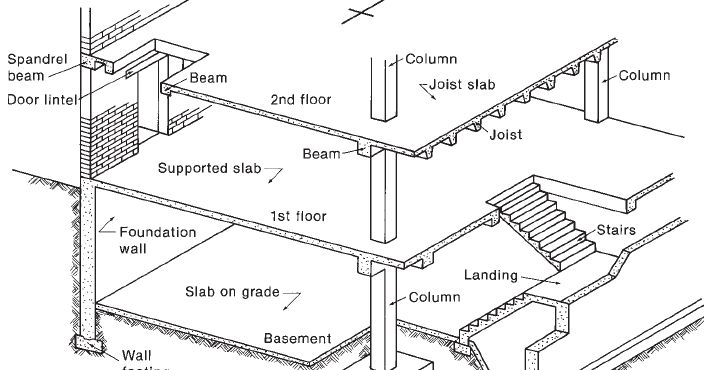

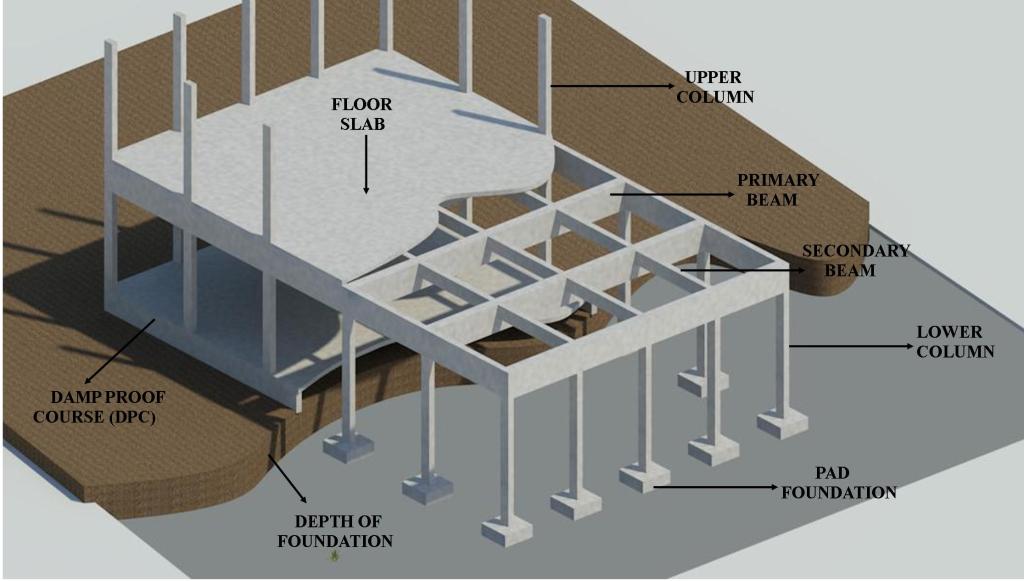

- Description: Concrete frames consist of interconnected columns and beams, forming a skeletal structure that supports floors and walls. Steel reinforcement is typically embedded within the concrete to enhance its tensile strength.

- Advantages: High strength and stiffness, fire resistance, good sound insulation, adaptable to various architectural designs.

- Applications: High-rise buildings, industrial facilities, parking garages, and infrastructure projects.

- 2. Concrete Walls:

- Description: Concrete walls can be load-bearing or non-load-bearing. Load-bearing walls support the weight of the structure above, while non-load-bearing walls act as partitions or cladding.

- Advantages: Durable, fire-resistant, soundproof, and provide excellent thermal mass. Can be reinforced with steel or fiber for added strength.

- Applications: Basement walls, retaining walls, shear walls in seismic areas, industrial buildings, and residential construction.

- 3. Concrete Slabs:

- Description: Concrete slabs form the horizontal surfaces of floors and roofs. They can be supported by beams, walls, or columns.

- Types:

- One-way slabs: Supported on two opposite sides, primarily bending in one direction.

- Two-way slabs: Supported on all four sides, bending in both directions.

- Flat slabs: Directly supported by columns, without beams, offering flexibility in layout and reduced floor-to-floor height.

- Waffle slabs: Two-way ribbed slabs that provide high strength-to-weight ratio, often used for large spans.

- Advantages: Fire resistance, sound insulation, and ability to carry heavy loads.

- Applications: Floors and roofs of various building types, parking decks, and bridges.

- 4. Tilt-Up Construction:

- Description: Concrete walls are cast horizontally on the ground (usually on the building slab), then tilted up into their vertical position using cranes.

- Advantages: Faster construction time, lower cost compared to traditional cast-in-place methods, improved quality control due to ground-level casting.

- Applications: Warehouses, retail buildings, industrial facilities, and office buildings.

II. Precast Concrete Structures:

Precast concrete involves casting concrete elements in a factory or controlled environment and then transporting them to the construction site for assembly. This method offers several advantages over cast-in-place construction.

- 1. Precast Panels:

- Description: Precast concrete panels are used for walls, cladding, and facades. They come in various shapes, sizes, and finishes.

- Advantages: Faster construction, improved quality control, reduced on-site labor, and aesthetic flexibility.

- Applications: Exterior walls, cladding for high-rise buildings, architectural features, and sound barriers.

- 2. Precast Beams and Columns:

- Description: Precast beams and columns are structural members that support floors and roofs. They are manufactured with precise dimensions and high strength.

- Advantages: Faster erection, consistent quality, reduced formwork, and long spans.

- Applications: Bridges, parking garages, industrial buildings, and commercial buildings.

- 3. Precast Hollow Core Slabs:

- Description: Hollow core slabs have longitudinal voids that reduce their weight while maintaining their structural strength.

- Advantages: Lightweight, long spans, fast installation, and good sound insulation.

- Applications: Floors and roofs in residential, commercial, and industrial buildings.

- 4. Prestressed Concrete:

- Description: Prestressed concrete involves tensioning high-strength steel tendons within the concrete before the application of loads. This increases the concrete’s load-carrying capacity and reduces cracking.

- Types:

- Pre-tensioned: Tendons are tensioned before the concrete is poured.

- Post-tensioned: Tendons are tensioned after the concrete has hardened.

- Advantages: Longer spans, reduced concrete volume, increased strength, and reduced deflections.

- Applications: Bridges, parking garages, high-rise buildings, and large roof structures.

III. Concrete Masonry Unit (CMU) Structures:

CMUs, also known as concrete blocks, are precast concrete units that are laid in a similar fashion to bricks. They are commonly used for walls and foundations.

- Description: CMUs come in various sizes, shapes, and densities. They can be reinforced with steel bars and filled with grout to increase their strength.

- Advantages: Durability, fire resistance, sound insulation, cost-effectiveness, and ease of construction.

- Applications: Foundations, load-bearing walls, partition walls, retaining walls, and firewalls.

IV. Shell Structures:

Concrete shells are thin, curved surfaces that enclose space. Their shape provides inherent strength, allowing them to span large areas with minimal material.

- Description: Shell structures can be constructed using cast-in-place or precast concrete. They come in various forms, including domes, vaults, and hyperbolic paraboloids.

- Advantages: Large clear spans, efficient use of materials, and aesthetically pleasing designs.

- Applications: Stadiums, auditoriums, exhibition halls, and industrial buildings.

V. Composite Concrete Structures:

Composite concrete structures combine concrete with other materials, such as steel, to enhance their performance.

- Description: Composite concrete structures leverage the compressive strength of concrete and the tensile strength of steel.

- Types:

- Steel-Concrete Composite Beams: Steel beams are encased in concrete, increasing their load-carrying capacity and stiffness.

- Steel-Concrete Composite Columns: Steel tubes are filled with concrete, providing enhanced strength and fire resistance.

- Advantages: Increased strength, stiffness, and load-carrying capacity compared to using either material alone.

- Applications: High-rise buildings, bridges, and industrial buildings.

Considerations When Choosing a Concrete Building Structure Type:

Selecting the appropriate concrete building structure type requires careful consideration of several factors:

- Structural requirements: Load-bearing capacity, span length, and seismic resistance.

- Architectural design: Aesthetics, shape, and spatial requirements.

- Budget: Cost of materials, labor, and equipment.

- Construction schedule: Time required for construction and erection.

- Site conditions: Accessibility, soil conditions, and environmental factors.

- Sustainability: Material sourcing, energy efficiency, and life-cycle impact.

Conclusion:

Concrete offers a wide range of possibilities for building structures, each with its own advantages and applications. Understanding the different types of concrete building structures, their characteristics, and the factors that influence their selection is essential for designing and constructing safe, efficient, and aesthetically pleasing buildings. By carefully considering the specific requirements of each project, architects and engineers can leverage the versatility and durability of concrete to create innovative and sustainable structures that stand the test of time. As technology advances, expect to see even more innovative concrete building structure types emerging, pushing the boundaries of architectural and engineering design.